Introduction to Biochar Business

Starting a biochar business presents a promising opportunity in the sustainable agriculture and environmental management sectors. Biochar, a form of charcoal used to improve soil health and sequester carbon, has gained significant attention for its potential to enhance soil fertility, increase crop yields, and mitigate climate change. To successfully enter this market, entrepreneurs must carefully consider biochar production equipment selection, feedstock sourcing, and return on investment (ROI) analysis.

Selecting the Right Equipment

- Types of Pyrolysis Equipment

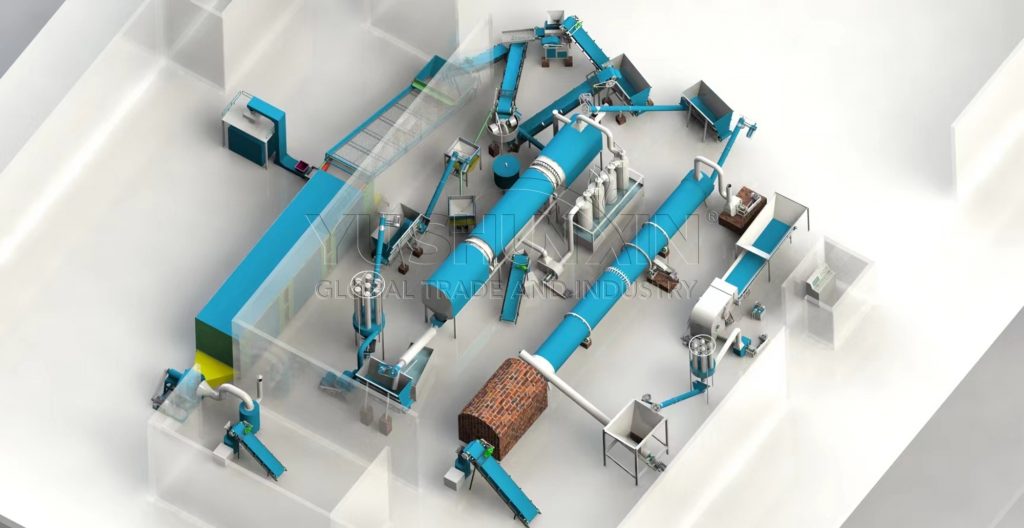

The core of a biochar business is the pyrolysis equipment, which thermochemically converts organic material into biochar. There are several types of pyrolysis systems, including batch and continuous systems. Batch systems are suitable for small-scale operations and are generally less expensive, while continuous pyrolysis systems can handle larger volumes and offer higher efficiency, making them ideal for larger enterprises.

- Key Considerations for Equipment Selection

When choosing pyrolysis equipment, consider factors such as capacity, efficiency, ease of operation, and maintenance requirements. It’s essential to select a system that aligns with your production goals and budget. Additionally, evaluate the equipment’s energy consumption and emissions to ensure compliance with environmental standards and maximize sustainability benefits.

Sourcing Feedstock for Biochar Production

- Types of Feedstock

The choice of feedstock significantly influences the quality and characteristics of the resulting biochar. Common feedstocks include agricultural residues (such as straw and husks), forestry by-products (such as sawdust and wood chips), and organic waste (such as food waste and manure). Each type has distinct properties and availability, affecting both the production process and the final product’s marketability.

- Sustainability and Sourcing Strategies

A sustainable feedstock sourcing strategy is crucial for a successful biochar business. Opt for locally available materials to reduce transportation costs and emissions. Establishing partnerships with farmers, forestry operations, and waste management facilities can ensure a steady supply of feedstock, supporting consistent biochar production and reducing raw material costs.

Conducting ROI Analysis

- Cost Factors

A comprehensive ROI analysis involves assessing both initial investment and ongoing operational costs. Initial costs include equipment purchase, site preparation, and installation. Operational costs encompass feedstock procurement, labor, energy, and maintenance expenses. Understanding these cost factors is essential for pricing your biochar competitively while ensuring profitability.

- Revenue Streams and Market Potential

Revenue from a biochar business can be generated through sales of biochar products and carbon credits. Evaluate market demand in agriculture, landscaping, and environmental remediation sectors to identify opportunities for sales growth. Additionally, explore the potential for earning carbon credits by sequestering carbon, providing an additional revenue stream.

Conclusion

Starting a biochar business requires careful planning and strategic decision-making in equipment selection, feedstock sourcing, and ROI analysis. By focusing on sustainable practices and understanding market dynamics, entrepreneurs can capitalize on the growing demand for biochar, contributing to environmental sustainability and achieving financial success. As the biochar market continues to expand, proactive and informed business strategies will be key to establishing a competitive edge in this emerging industry. Visiting: https://www.char-molder.com/product/biochar-production-equipment/

Leave a Reply