Introduction to Palm Shell Charcoal Production

The global demand for sustainable and eco-friendly fuel sources has stimulated interest in alternative charcoal production methods. Among these, palm shell charcoal has emerged as a promising option due to its high carbon content and low environmental impact. The complete palm shell charcoal making process transforms raw palm shells into valuable charcoal through several stages. Understanding this process can help businesses and environmental advocates appreciate the benefits and intricacies of producing palm shell charcoal.

Collection and Preparation of Raw Material

The first step in the palm shell charcoal making process is the collection and preparation of raw palm shells. These shells are byproducts of the palm oil industry, making them an abundant and cost-effective resource. Once collected, the shells are cleaned to remove any impurities such as soil or organic matter. This cleaning step is critical as it ensures the quality and purity of the final charcoal product. Prepared shells are then resized, if necessary, to facilitate even carbonization in subsequent stages.

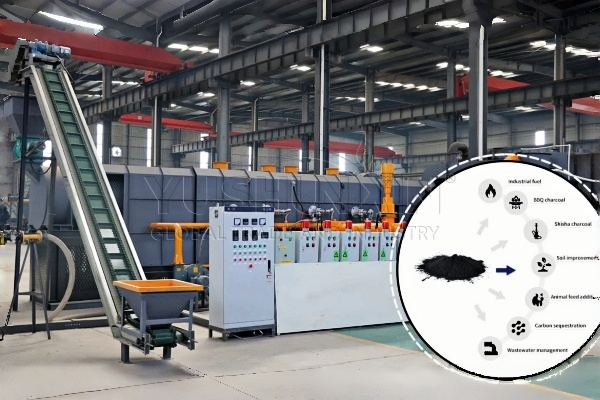

Carbonization Process

The core of the palm shell charcoal making process is carbonization, which involves heating the shells in a low-oxygen environment to transform them into charcoal. This process can be conducted in a carbonization furnace or kiln, where temperatures typically range from 400°C to 600°C. The lack of oxygen prevents the shells from combusting, allowing them to decompose chemically into charcoal. During carbonization, volatile substances such as water vapor and gases are released, leaving behind solid carbon-rich charcoal. This stage is crucial as it determines the quality and characteristics of the final product.

Cooling and Collection

After carbonization, the hot charcoal must be cooled before it can be handled safely. Cooling is usually done by allowing the charcoal to sit in a sealed chamber, often with the use of a cooling conveyor. This gradual cooling process is vital to prevent the charcoal from igniting when exposed to air. Once cooled, the charcoal is collected and may be further processed depending on its intended use. For example, it can be crushed into smaller pieces or ground into powder for use in various applications.

Packaging and Distribution

The final stage of the palm shell charcoal making process is packaging and distribution. The charcoal is packaged in bags or bulk containers, ready to be distributed to markets or industrial users. Proper packaging is essential to prevent moisture from affecting the charcoal’s quality during transportation and storage. With its high carbon content and low ash production, palm shell charcoal is suitable for various applications, including fuel for cooking and heating, as well as in industrial processes.

Conclusion

The complete palm shell charcoal making process efficiently converts waste palm shells into valuable charcoal, offering both economic and environmental benefits. By utilizing an abundant agricultural byproduct, this process supports sustainability and resource conservation. As industries continue to seek greener alternatives, palm shell charcoal stands out as a viable solution that aligns with global efforts toward sustainable development. Understanding this process is key to maximizing its potential and contributing to a more sustainable future. Visiting: https://www.ysxcharpro.com/product/palm-charcoal-production-line/

Leave a Reply