The cost of a charcoal briquette machine is not a single figure but a spectrum, heavily influenced by production scale, automation level, and build quality. Prices can range from a few hundred dollars for a basic manual press to over $100,000 for a fully automated industrial production line. Understanding the distinction between small-scale and industrial models is key to making a sound investment that matches your output goals and budget.

Key Factors Determining the Price

Several core elements drastically affect the machine’s price tag:

- Capacity & Output: This is the primary cost driver. Price escalates with the machine’s hourly or daily production capacity (e.g., 100 kg/h vs. 2,000 kg/h).

- Power Source & Pressure: Machines are powered electrically, hydraulically, or mechanically. High-tonnage hydraulic or screw press models, which create denser, higher-quality briquettes, are more expensive than simple mechanical stamping presses.

- Automation Level: Manual or semi-automatic machines requiring constant operator involvement cost less. Fully automatic systems with integrated feeders, conveyors, and PLC control panels command a premium but offer efficiency and labor savings.

- Build Quality & Materials: Heavy-duty steel construction, hardened alloy molds, and premium components (like hydraulic systems or motors) ensure durability and longevity but increase the initial cost.

Small-Scale & Starter Models ($500 – $10,000)

This category is designed for hobbyists, small farms, or very small businesses. It often includes manual piston presses, small screw extruders, and low-capacity stamping machines.

- Typical Cost: Ranges from $500 to $3,000 for basic models. More robust small-scale setups with a simple conveyor can reach $5,000-$10,000.

- Features: Lower output (50-300 kg/h), often semi-automatic or manual operation, simpler construction. They are suitable for uniform, powdered raw materials and have higher labor requirements per unit produced.

- Best For: Testing the market, producing for local/niche sales, or supplemental income.

Industrial Production Lines ($15,000 – $150,000+)

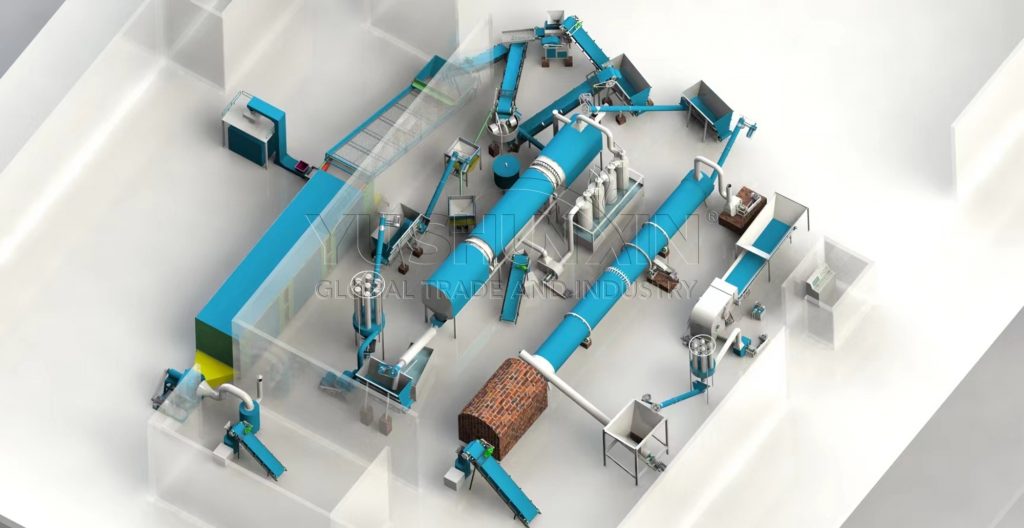

These are complete systems engineered for continuous, high-volume commercial production. They are built for reliability, efficiency, and minimal operator intervention.

- Typical Cost: A standard industrial screw press or hydraulic briquetting line starts around $15,000 to $50,000. Large, fully integrated lines with crushers, dryers, mixers, conveyors, and automated packing can easily exceed $100,000.

- Features: High output (1,000 kg/h and far beyond), full automation with consistent density control, ability to handle a wider variety of raw material sizes and moisture contents (often with pre-processing equipment included), and much greater durability.

- Best For: Large-scale businesses supplying retailers, distributors, or for export markets where consistent quality and volume are critical.

Beyond the Machine: Total Investment Cost

The machine itself is only part of the financial picture. A functional production line requires ancillary equipment like a crusher, dryer, and mixer, which can add thousands to the cost. Additionally, factor in costs for installation, electrical work, spare parts (especially molds/rollers), and ongoing maintenance. Energy consumption for industrial models is also a significant operational expense.

Making the Right Choice

Your choice should be guided by a clear business plan. Assess your raw material supply, target market volume, and available capital. While a small machine has a lower entry cost, an industrial model offers a lower cost-per-unit produced at scale, leading to greater long-term profitability. Prioritize suppliers who offer strong technical support and warranty, as downtime in a production environment is costly. Ultimately, investing in the correct capacity and quality for your needs is the most cost-effective decision you can make. Visiting: https://www.char-molder.com/product/charcoal-briquette-machine-price/

Leave a Reply