Investing in a charcoal briquette making machine is a significant step for any business in the biomass fuel sector. The price range is vast, from a few thousand dollars for a simple press to over $100,000 for a fully automated line. Understanding the key factors that determine this cost is essential for making a smart purchase that balances your budget with your production needs. The final price is rarely about the machine alone; it reflects its capability, durability, and the support that comes with it.

1. Production Capacity and Output

This is the most direct cost driver. Machines are rated by their hourly output (e.g., 500 kg/hr, 2,000 kg/hr). A small, manually-fed machine for a startup workshop will cost a fraction of a high-volume, continuous-feed system designed for industrial-scale production. Your required output directly dictates the machine’s size, motor power, and structural robustness, all of which influence the price of charcoal briquette machine.

2. Level of Automation

The automation spectrum is wide. A manual or semi-automatic machine, requiring an operator to feed material and remove briquettes, is the most affordable. A fully automatic system with integrated feeders, conveyors, and automated cutting/packaging dramatically increases efficiency and labor savings, but also the upfront investment. Every added automated component adds to the cost.

3. Material of Construction & Key Parts

The durability of the machine hinges on the materials used. The molding press (or screw extruder) and the die/mold itself endure extreme pressure and abrasion. Machines using high-grade, heat-treated alloy steels for these critical parts will cost more than those using standard carbon steel but will last much longer and require less downtime for part replacement.

4. Power Source and Motor

The power rating (in kW or HP) of the main motor correlates with capacity and cost. Additionally, the choice between an electric motor, diesel engine, or a PTO-driven model for tractor operation affects price. Electric models are common, but diesel or gasoline engines add cost and flexibility for locations with unreliable electricity.

5. Brand Reputation and Origin

Established brands with a history of reliability and engineering excellence command a premium over lesser-known or generic manufacturers. Furthermore, the country of manufacture significantly impacts cost. Machines imported from Europe or North America are typically more expensive than comparable models from Asia, though this often reflects differences in manufacturing standards, material quality, and intellectual property.

6. After-Sales Service and Support

The initial purchase price is just one part of the total cost of ownership. A supplier offering comprehensive warranties, readily available spare parts, and reliable technical support (including installation guidance and troubleshooting) often has a higher price tag. This support is invaluable for minimizing costly production halts.

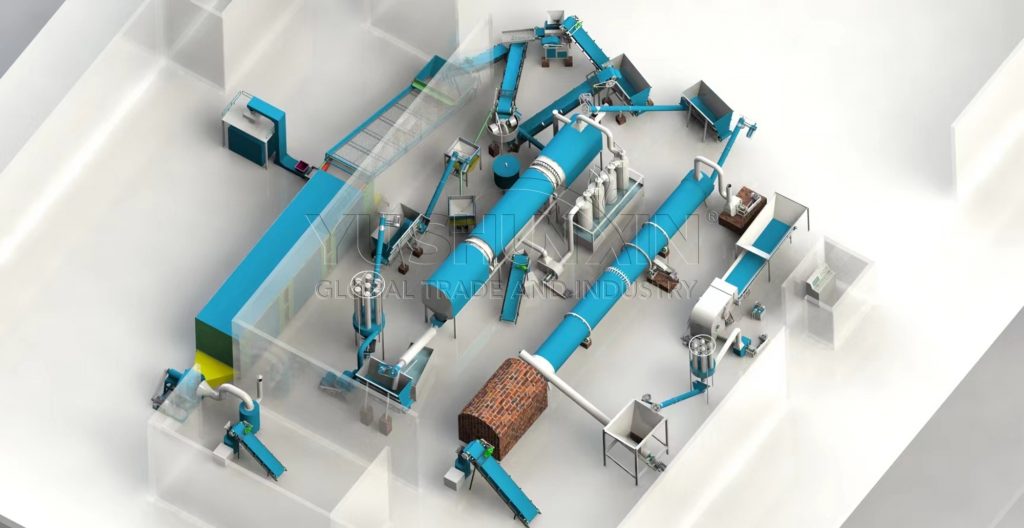

7. Auxiliary Equipment Integration

A briquette machine rarely works in isolation. The quoted price can vary if it includes or is designed to integrate seamlessly with essential auxiliary equipment, such as a crusher, dryer, mixer, or conveyor system. A “complete line” price will be higher than that of a standalone press. Visiting: https://www.char-molder.com/product/charcoal-briquette-machine-price/

Leave a Reply