Introduction

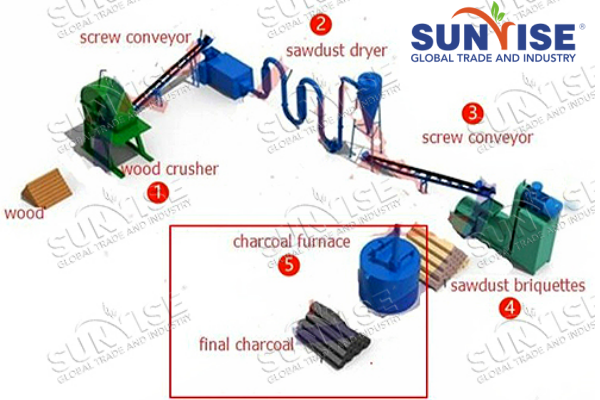

The use of a charcoal extruding machine to produce sawdust biochar briquettes is an efficient and sustainable method of converting biomass waste into valuable products. This process involves several steps, each critical to ensuring the quality and efficiency of the final biochar briquettes. This passage will guide you through the entire process, from preparing the raw materials to extruding and drying the briquettes.

Preparing the Raw Materials

Collecting Sawdust

The first step in producing sawdust biochar briquettes is to gather the sawdust. This can be sourced from woodworking shops, sawmills, or other facilities that generate wood waste. It is crucial to ensure that the sawdust is free from contaminants such as plastic, metal, or chemical treatments, as these can affect the quality of the biochar and potentially damage the machine.

Drying the Sawdust

The moisture content of the sawdust is a critical factor in the briquetting process. Ideally, the sawdust should have a moisture content of 10-15%. Wet sawdust can be dried using a rotary drum dryer or a simple sun-drying method. Ensuring the correct moisture level is vital for achieving high-quality briquettes and preventing clogging or damage to the extruding machine.

Preparing the Charcoal Extruding Machine

Setting Up the Machine

Before starting the extrusion process, set up the charcoal extruding machine according to the manufacturer’s instructions. This involves securing the machine on a stable surface, connecting it to a power source, and ensuring all components are correctly assembled. Safety precautions, such as wearing protective gear and ensuring proper ventilation, should also be observed.

Adjusting the Parameters

Adjust the machine’s parameters, such as temperature, pressure, and extrusion speed, based on the type of sawdust and desired briquette characteristics. These settings can vary depending on the specific machine model and the type of biomass being processed. It is advisable to start with the manufacturer’s recommended settings and make adjustments as necessary based on initial output quality.

The Extrusion Process

Feeding the Sawdust

Once the machine is ready, feed the dried sawdust into the hopper. Some machines may have an automatic feeding mechanism, while others require manual feeding. Ensure a consistent feed rate to maintain uniformity in the briquettes and prevent the machine from becoming overloaded.

Extruding the Briquettes

As the sawdust is fed into the machine, it passes through a high-pressure chamber where it is compressed and heated. This process binds the sawdust particles together, forming solid briquettes. The extruded briquettes will emerge from the machine in a continuous form, which can then be cut to the desired length using a cutting mechanism or manually. Click here to get more detailed information.

Post-Production Processing

Cooling the Briquettes

After extrusion, the briquettes may still be hot and slightly soft. Allow them to cool and harden in a well-ventilated area. Cooling can take several hours, depending on the ambient temperature and the size of the briquettes. Proper cooling is essential to ensure the briquettes retain their shape and structural integrity.

Drying and Storage

Although the briquettes should be dry enough after the extrusion and cooling process, an additional drying step can enhance their quality and shelf life. Place the briquettes in a drying area or use a drying oven to remove any remaining moisture. Once fully dried, store the briquettes in a cool, dry place to prevent mold growth and deterioration.

Conclusion

Producing sawdust biochar briquettes using a charcoal extruding machine involves several meticulous steps, from preparing the raw materials to the final drying and storage of the briquettes. By following this detailed guide, you can ensure the efficient and effective production of high-quality biochar briquettes. This process not only adds value to biomass waste but also contributes to sustainable energy solutions and environmental conservation. Understanding and carefully executing each step will lead to optimal results and a successful briquetting operation.

Leave a Reply